Frequently Asked Questions | Nacflex

Frequently Asked Questions

- WHAT IS NACFLEX CONDUIT CABLE?

- WHAT ARE THE ADVANTAGES OF NACFLEX CONDUIT CABLE?

- HOW MUCH TIME DO I SAVE WITH NACFLEX CONDUIT CABLE?

- WHERE TO USE NACFLEX CONDUIT CABLE?

- CAN I REMOVE OR ADD CABLE FROM/TO THE CONDUIT?

- WHAT DOES FLEXIBLE SELF-WINDING CONDUIT MEAN?

- WHAT ARE THE FEATURES OF NACFLEX CONDUITS ?

- WHY IS IMPACT STRENGTH IMPORTANT FOR SPIRAL CONDUITS?

- WHAT IS THE DIFFERENCE BETWEEN HF AND NON-FLAME-PROPAGATING CONDUITS?

- WHAT IS THE DIFFERENCE BETWEEN PVC CONDUITS AND POLYPROPYLENE CONDUITS?

- WHAT DO NACFLEX CONDUIT COLORS MEAN?

- IS THERE ANY SPECIFIC CERTIFICATE FOR THE CONDUIT CABLE?

- HOW CAN I UTILIZE NACFLEX CONDUIT SCRAPS?

It is a type of electric wiring having ready cables within the conduit by eliminating the labor of passing cables through the conduit, which is a traditional wiring system in electric wiring. With Nacflex Conduit Cable, it is possible to perform piping with different combinations of conduits of any diameters.

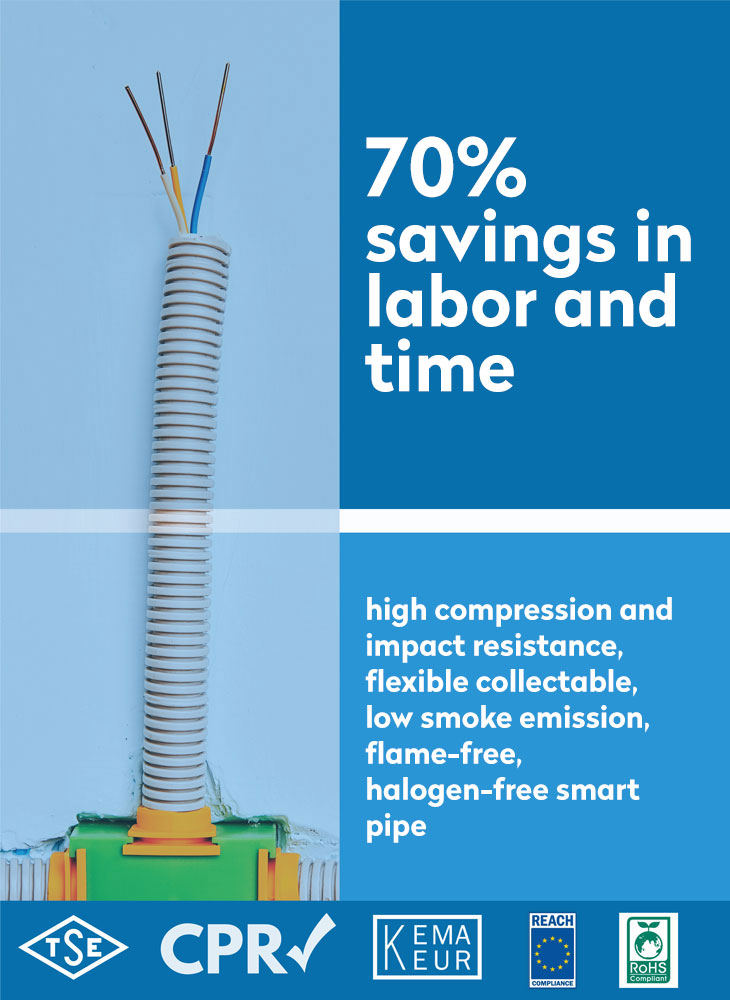

Nacflex Conduit Cable provides 70% saving in labor and time by eliminating the system of passing cables through the conduit by using springs and guides. A single person can perform the work alone.

3×1,5 products were installed in an area of 1000 m2. It was installed by 4 people in 48 hours with the old system. With Nacflex Conduit Cable, 2 people completed the electric wiring in 16 hours.

Nacflex Conduit Cable products can be applied under concrete, plaster, floor, wall, or ceiling. In addition, they are easy-to-apply and useful in all areas such as suspended ceilings, mobile walls, prefabricated houses, etc. Nacflex Conduit Cables are not recommended to mount on exterior surfaces.

Of course, yes. The cables of Nacflex Conduit Cable are not attached to the conduit. Therefore, you can easily remove cables from the conduit. You can also add new cables as long as allowed by the diameters.

The diameter of a conduit, which passed the laboratory tests with a load of 750 Newton in 5 cm, can reduce up to 50%. When the load is released, the diameter should restore to its original value with a reduction of less than 10%. The conduits having this feature are flexible self-winding pipes. The conduits not having this feature cause difficulty in adding and removing cables and become inoperative

Nacflex Conduits are flexible, self-winding, non-flame-propagating conduits with a compressive strength of 750 Newton, impact strength of 6kj, and thermal resistance of -5° and 90°.

Spiral conduits are used as cable protection. Their status of operating and installation at low and high temperatures is checked. Particularly the conduits with a low impact strength during the installation at low temperatures are broken and become inoperative as a result of the impact they are subject to. Therefore, conduits with a high impact strength should be preferred. Polypropylene conduits are the most important raw materials for their high mechanical and thermal resistances. Nacflex Conduits are made of 100% polypropylene.

The regulations for spiral conduit standards are EN 61386-1 and EN 61386-22. Under these regulations, a product is subject to 12 classifications. The 11th class is the flame-propagating or non-flame-propagating type class. Only this specification is taken into consideration for spiral conduits. Nacflex Conduits are classified as non-flame-propagating.

Compared to PVC conduits, polypropylene conduits have a 3 times higher impact strength, a higher low and high thermal resistance; they are flexible self-winding, environment-friendly LSZH and have therefore a very low toxic smoke emission; and they do not contain heavy (e.g. lead) or chloric metals. It is recommended to use polypropylene in installations for the health of humans and nature.

The conduit colors are not based on any standard. As Nacflex Conduit Cable, we produce grey conduits for energy cables, blue conduits for data cables, green conduits for coaxial cables, and red conduits for fire alert cables in order to both easily distinguish in the storage system and to rapidly distinguish between energy and weak current cables in the installation.

For conduit cable types, cables and conduits are generally certified individually. As Nacflex Conduit Cable, we have TSE, CE, KEMA-KEUR, REACH, and ROSH certifications for our conduit products. Besides all these standards, we use CPR-certified products for cable products. In addition, with our international KEMA-KEUR certification, we have set a standard for all products in terms of the conduit cable which is used for the first time around the world.

All our products are 100% recyclable polypropylene products. Your packing and scrap conduits should be taken to your local collection authority to send to a plastic regeneration facility. Likewise, our product packing is also polyethylene product. The recycling method applies also to these products.